DTF printing (Direct-to-Film) has revolutionized the way custom clothing is created. Simple in essence, but incredibly flexible in capabilities, this technology allows entrepreneurs to literally launch a mini-production from scratch without bulky screens, unnecessary waste and huge investments. Some call it the “quiet revolution,” while others call it the “second wind” of the textile business. But one thing is clear: DTF is not a temporary trend, but a solid tool for those who value speed, quality and independence.

What Is Hidden Behind The Abbreviation DTF

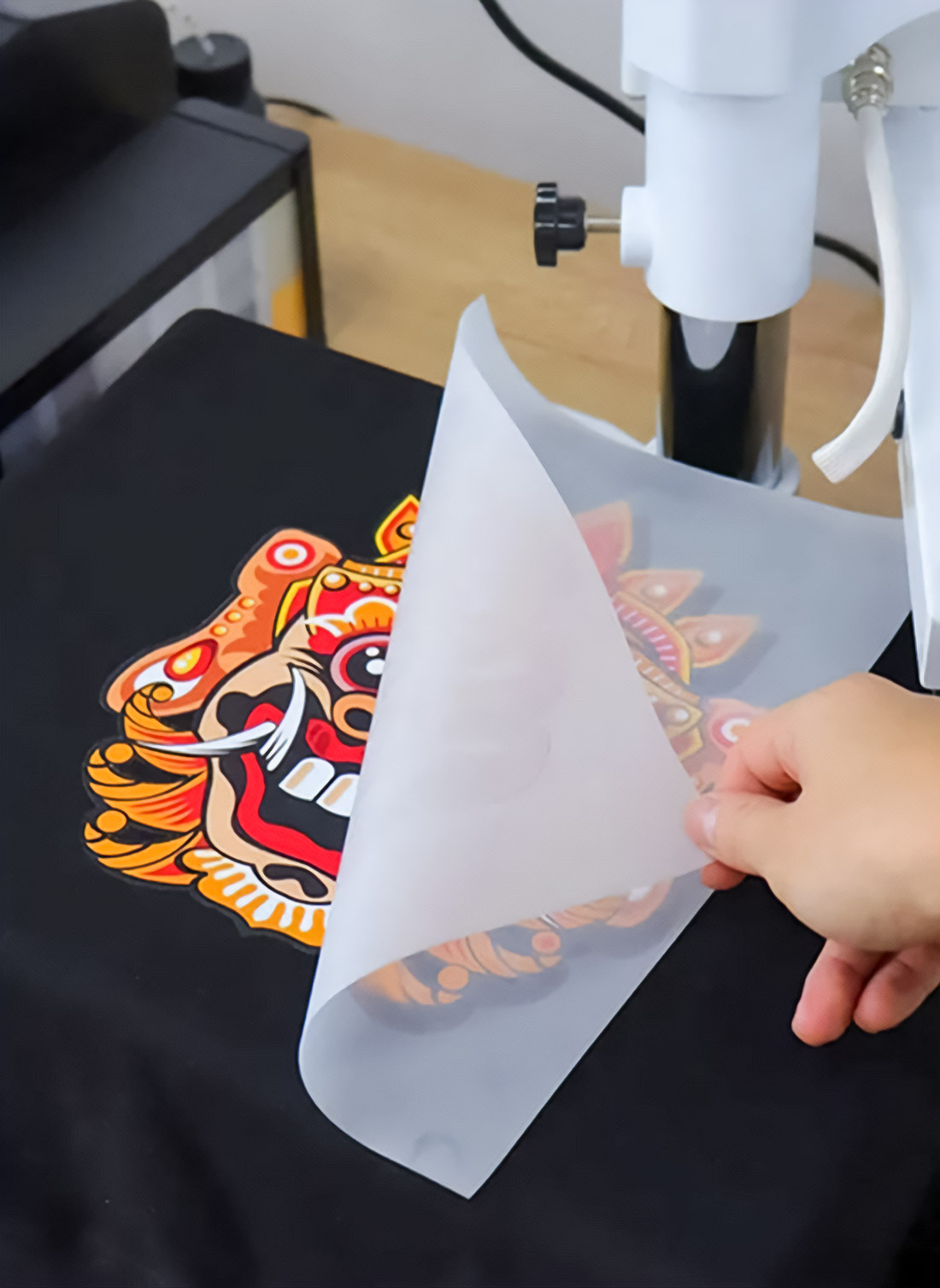

The point is simple. The image is printed on a transparent PET film with water ink in the color model CMYK + White. Then an adhesive powder is applied to the fresh layer, melted, fixed and transferred to the fabric through a thermal press. It turns out to be a stable, elastic and bright print.

Every step is like an artist’s exact touch:

- Layout creation and color profile verification (ICC);

- Print with a resolution of at least 300 DPI;

- Powder application and uniform distribution;

- Drying (curing**) and temperature control;

- Pressure transfer and final pressing.

No pre-treatment of the fabric, no “dirty” screens, just precise mechanics, the right temperature and a little experience.

Why Small Businesses Should Pay Attention

DTF does not require thousands of copies. You can print one, sell one, and release a new series tomorrow. Minimum risks, maximum flexibility. This technology has become a lifesaver for small brands that want to keep up with trends but are unwilling to spend capital on a warehouse.

The benefits are tangible:

- Printing on cotton, polyester, leather, blends;

- Eco-friendly water-based ink instead of toxic solvents;

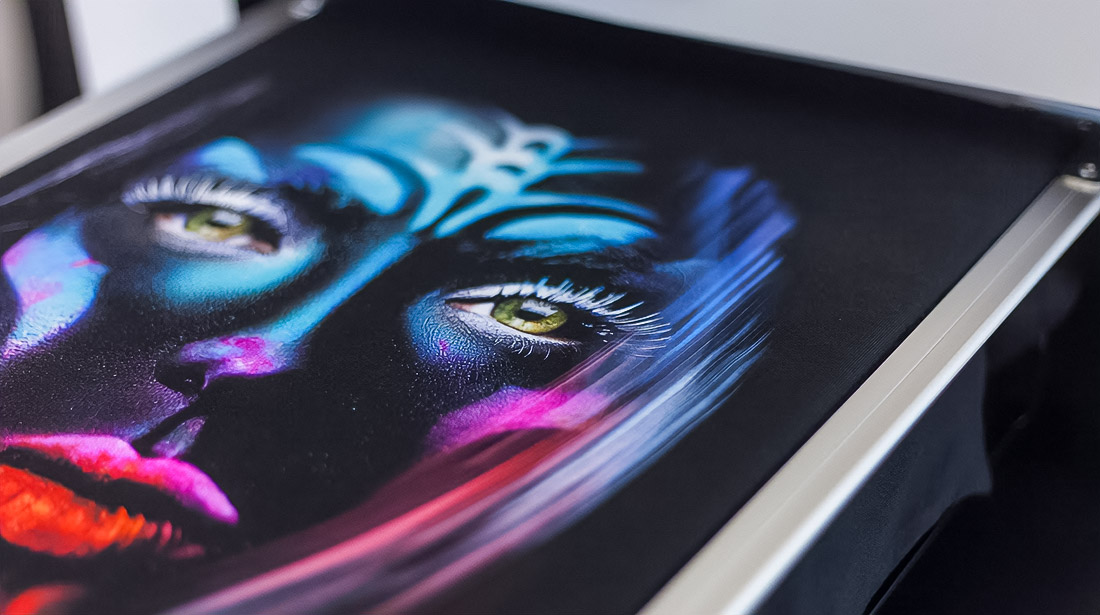

- Rich colors even on dark fabrics;

- Save on preparation no screens, frames or emulsions.

According to experts, the global market for custom clothing has grown from 3.64 billion dollars in 2020 to a projected 7.57 billion by 2028. And the segment of DTF printing by 2030 may reach 7.9 billion dollars. Demand is growing because small brands have found a way to create products quickly, without excess and with high quality.

Today, many local entrepreneurs search for dtf printing near me to find reliable workshops offering same-day transfers, personalized color matching, and consistent production quality proving that accessibility is as important as innovation.

How To Equip A Workspace

What is needed is not a factory, but a reasonable organization. A printer, a thermal press, a powder dryer, a computer withRIP software, a few consumables, and you can work. The main thing is order and safety:

- Reliable ventilation,

- Stable power supply with protection,

- Clean, dust-free area,

- Accounting of consumables.

One square meter of chaos can turn a good order into a failure. Thoughtful workflow saves hours and nerves, especially during the sales season.

Color, Precision, Durability

DTF requires discipline. The color profile, regular cleaning of the printing heads, and control of the drying temperature all affect the final result. Calibration is like tuning a musical instrument: the slightest deviation, and instead of harmony, noise. The right approach gives the result prints do not crack, do not fade, do not lose elasticity even after dozens of washes.

Automation And Control

Even a small production can be smart. Order management systems, inventory accounting, SOP procedures, CRM systems planners like Trello or Asana turn chaos into a flow. Track lead time, print rejection rate, unit cost, ROI per design these indicators will tell you more than any reports. When the numbers are under control, quality and profit grow in parallel.

Marketing And Brand

A brand does not start with a logo, but with a feeling. How the packaging smells, how the ribbon looks, how your tone sounds in the letter all this is part of the identity. Create corporate colors, design a minimalistic logo, add a thank you card, a QR code, and a story about yourself. Show processes, mistakes, and orders the audience loves transparency. Work with social networks, try white-label, release limited drops, create referral programs. Your clients are the best marketers if they have something to be proud of.

30-Day Start Plan

- Days 1-5 — determine the style, test the designs, select suppliers.

- 6-12 — install the printer, calibrate, and check the PET films.

- 13-20 — test batches, color adjustment and drying.

- 21-28 — process optimization, packaging, accounting of consumables.

- 29-30 — metric analysis, website launch, first advertisement.

DTF printing is not just a method, but an ecosystem where technology, creativity and calculation are combined. It gives you the opportunity to create, test, sell and grow without unnecessary investments. This is a technology for those who love details, believe in quality and want to manage every stage from the idea to the finished product. DTF is a tool that helps small businesses become visible, sustainable, and profitable.

An athlete, a lover of delicious food. Let’s chat.