Thermal growth is a simple phenomenon in essence, but insidious in its consequences. The metal, heated during operation, expands. The expansion is microscopic, sometimes only a few thousandths of an inch, but it breaks the exact alignment and destroys the harmony of the rotating nodes. Once the shaft leaves the axle, the whole machine begins to live a different life with vibration, noise and wear.

Why Electro Mechanical Company Specialists Monitor Thermal Growth

The formula T × L × C is elementary at first glance. Temperature, length, expansion coefficient. Three magnitudes, one product, and we get an offset. In reality, this simplicity turns into a whole science of reliability. For example, a 10-inch steel shaft increases by 0.00444 inches when heated at 60°F. A 12-inch cast-iron part will extend by almost 5 mils at a temperature difference of 70°F. Five thousandths of an inch! And this is already enough to cause misalignment and destroy the bearings.

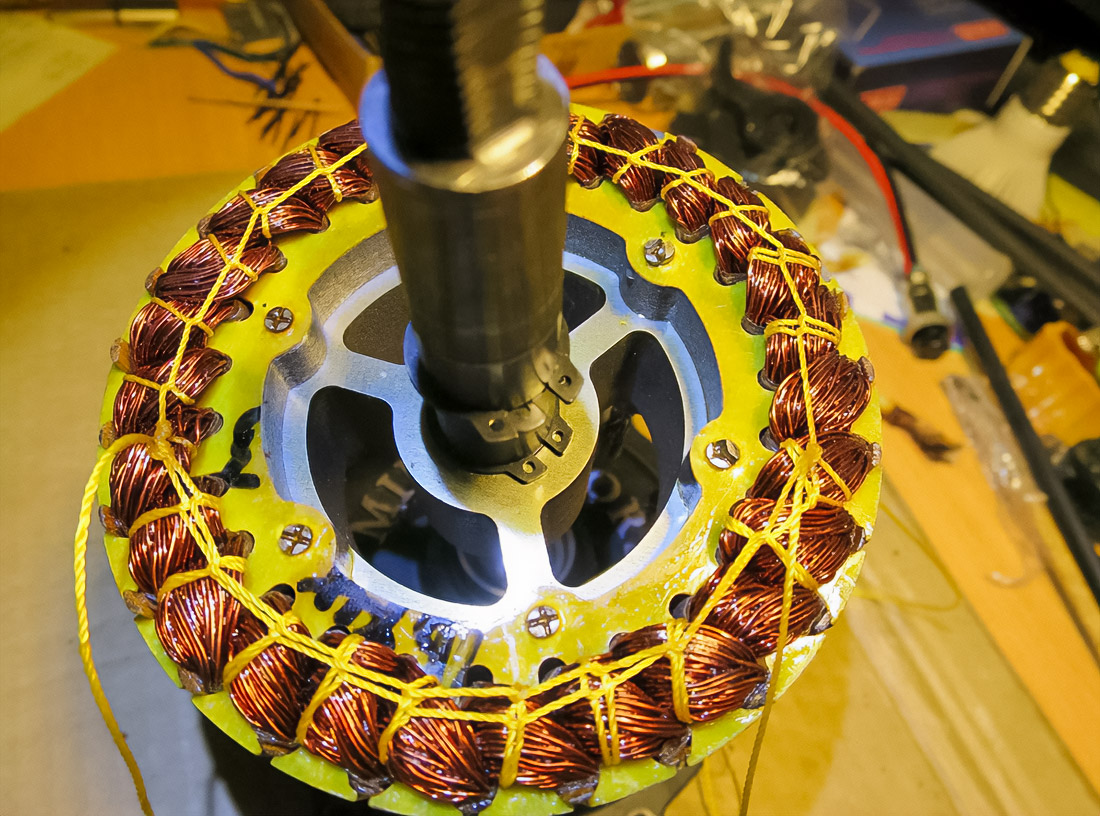

The compressor heats up quickly to 140°F, while the engine stays at 70°F. Their axes are no longer collinear. The bearings are overloaded, the grease burns out, and instead of smooth running, we get vibration, noise, and increased fatigue stresses. Vibration is a sure sign of trouble. It causes structural stress, reduces the service life of nodes and can lead to catastrophic failure. An unbalanced rotor is one of the main reasons for the failure of electric motors, and an <electro mechanical company often provides the expertise to detect these misalignments early and ensure reliable operation.

To compensate for thermal expansion, engineers apply “intentional” displacement during installation. For example, the motor is placed 4.4 mils below the pump level. When the temperature equalizes, the shafts are aligned. This solution is checked by a test run: the machine is running, heats up, stops, and the measurements confirm the correctness of the calculations. An accurate calculation here turns into a guarantee of reliability.

But thermal growth is never uniform. The front of the machine is cooled by a fan, the back is overheated, and the materials expand at different rates. Add to this the influence of pipelines that pull the hull in different directions, and the task becomes more complicated. Even a difference of only 10 °F for a turbine can shift the reference points by 2-4 mils. In high-speed machines, such values become critical.

Modern alignment methods are based on laser systems. The transmitter and detector record the movement of the shafts in real time. In one case, the transmission in the power unit rose by 0.53 mm at an operating temperature of about 80 °C. The horizontal displacement turned out to be insignificant, but the temperature difference between the generator and the box 30 °C caused the increase. These data helped to align the assembly correctly and avoid premature wear.

Thermal growth can only be partially reduced: lubrication reduces friction, ventilation prevents overheating, and good electrics eliminate local overheating zones. But it is impossible to completely stop the expansion. It can only be calculated, taken into account, and used as a setting parameter. It is not the struggle with physics that is important here, but the correct interaction with it.

The topics of thermal growth and balancing combine material physics, vibration diagnostics, dynamic alignment techniques, and operational practices. This body of knowledge enables the engineer to predict the future behavior of the machine and compensate for it in advance. This creates conditions for a long service life of bearings, minimizing downtime and stable operation of the entire production.

Thermal growth is not a textbook theory. This is the living reality of every start and every stop. Ignoring it means shortening the life of the machines and risking safety. Applying the T × L × C formula, performing laser alignment, taking vibration data into account, and making test runs is the way to turn risk into a manageable amount and give the technique a chance to work long and trouble free.

An athlete, a lover of delicious food. Let’s chat.